-

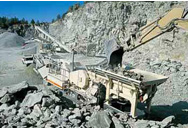

Мобильная дробилка

- пятивалковая мельница бу

- вибрационный грохот 200tph

- немецкий сделал карьер дробилка каменная дробилка

- Теория подземной добычи угля

- песка завода в УЗБЕКИСТАНЕ

- Мини дробильная установка для мелкомасштабной добычи

- цена щековой дробилки производительностью 50т

- Камень щековая дробилка цена Видео щековая дробилка

- оборудование для каменной дробилки в индии

- технические данные ГСА дробилки

- устройство для измельчения картошки

- деревянные мельницы цены

- каменная дробильная установка с

- Каталог деталей конусной дробилки

- Полиэтилен шлифовальный станок

- используется каменная дробилка для продажа в КЕНИИ

- дробилка валковые для шпал

- kontruksi каменная дробилка Индонезия

- запасные части для каменной дробилки тамилнад

- coal mill puffs explosions

<мобильного влияние доломит цена дробилка в Малайзии

A statistical analysis of coalmine fires and explosions in China

2019.1.1 About 55% of the gas explosions occurred in coalmines with low methane-gas emission rates. Coal dust explosions were responsible for about 59% of the fires and

Read More

Dynamic steam inerting system for a ball tube mill

2017.8.29 This paper provides nformation on the nature and circumstances of the explosions experienced in a ball tube mill system of a subbituminous coal- fired steam

Read More

Coal Pulverizer Explosions - Babcock Power

2023.9.18 In this paper the term "explosion" encompasses both severe puffs (structure deformation) and true explosions (containment breaching). The term "unit"

Read More

Fire and Explosion Prevention in Coal Pulverizing

2023.9.18 Explosions consistently occur when the coal air mixture is leaner than normal, either when initating coal feed on mill start-up, stopping coal feed on shutdown,

Read More

Coal Pulverization System: Explosion Prevention and

2017.1.5 Explosion Prevention and Process Control. Abstract: A pulverized coal processing system for produc-ing coal powder used in aluminum alloy smelting process

Read More

Mill Inerting Systems Presentation to the ASBCUG

2018.6.7 Mill inerting is regarded as the principal approach or engineering control to prevent mill fires explosions. People working in our industry use the term “inerting”

Read More

Mill Inerting and Pulverizer/Mill Explosion Mitigation

2018.6.7 Coal Mills are the Heart of a Coal Fired Plant Maximum capacity, reliability and performance of your operation rely on the critical roles that your coal mills perform:

Read More

How accurate primary airflow measurements

2006.5.15 Combustion. The immediate effect of high primary air (PA) flows is on combustion of pulverized coal. Burner coal nozzle exit velocities are vey dependant on the level of PA flow. High PA flows...

Read More

IJERPH Free Full-Text Analysis of the Interaction

2022.1.17 Bagherpour et al. assessed the safety risk in Iranian coal mines from the perspective of preventive–preparative measures and indicated that methane explosions, coal dust explosions and traffic

Read More

Pulverizer Fire and Explosion PDF Explosion Combustion

2015.11.26 Explosions in a pulverized coal system are normally called puffs. A mill puff is an explosion in the mill system caused by an explosive combination of coal, air and temperature. Mill puffs most often originate in the under bowl area and can cause very destructive damage to the primary air ducting. Mill puffs or explosions can be very

Read More

Mill Inerting and Pulverizer/Mill Explosion Mitigation

2018.6.7 People working in our industry use the term “inerting” loosely and sometimes incorrectly when describing systems that prevent mill explosions, puffs or fires. Systems often named as “inerting systems” by coal fired power plant personnel include: Steam Inerting Systems. Water fogging or deluge systems.

Read More

Coal Pulverizer Explosions - Babcock Power

2023.9.18 Coal Pulverizer Explosions by R. C. Carini Manager Administrative Services Research and Development ... In this paper the term "explosion" encompasses both severe puffs (structure deformation) and true explosions (containment breaching). ... 1 160 Mills in 258 Units o o Explosions per Year per Unit b, 00000 00 00 0 0 0 0 00000 000

Read More

Proactive Strategies for Dealing with Combustible Dust

2011.5.1 Friability can result in dangerous quantities of fine coal fragments, dangerous combustible dust, and higher dust emissions (Figure 1). 1. Falling to pieces. This 5-day-old undisturbed coal ...

Read More

sbmchina/sbm reasons for explosions al tube mills.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Read More

GitHub

causes of coal mill e plosions or fires. coal mill explosions causes. coal mill explosion study vrystaatboranklubcoza Explosion Coal In The Mill And explosion hazards of coal dust

Read More

Applied Sciences Free Full-Text Industrial Dust Explosions

2020.12.21 This paper first addresses the question: what is a dust explosion? Afterwards, some specific issues are briefly reviewed: materials that can give dust explosions, factors influencing ignitability and explosibility of dust clouds, the combustion of dust clouds in air, ignition sources that can initiate dust explosions, primary and

Read More

CDC - Mining Topic - Explosion Prevention - NIOSH

2022.10.6 The NIOSH Mining Program conducts research to identify and then mitigate the causes of underground coal mine explosions. Research strategies include eliminating ignition sources, minimizing methane concentrations and coal dust accumulations, applying proper dispersible rock dust in sufficient quantity at all locations,

Read More

possible causes of coal mill fires - stone-pulverizer

2019.3.26 cause of coal mill fire - pochiraju.co. There was no word late Wednesday night on a possible cause. ... the bridge and then we seen fire on the southeast side here where the coal goes in," he said. Get Price. ... Dec 25, 2013 ... causes of explosion in coal mill causes of coal mill explosions or fires ... Sudden coal hang-up in one or more ...

Read More

Fire and Explosion Prevention in Coal Pulverizing

2023.9.18 Explosions consistently occur when the coal air mixture is leaner than normal, either when initating coal feed on mill start-up, stopping coal feed on shutdown, or when equip- ment problems cause inadvertent loss of feed. Upon loss of feed to a pulverizer, the coal/ air mixture in the system becomes leaner and the coal dust will

Read More

DISCUSSION ON SAFETY PRODUCTION OF COAL MILLING

2022.1.27 1 Potential safety hazards in the coal mill system. 1.1 Spontaneous combustion occurs. The process of cement production determines the need to use a large amount of coal. The use of coal is mostly ...

Read More

Coal Pulverization System: Explosion Prevention and

2017.1.5 The explosibility of the coal used in the system was measured, and the hazards of the process were analyzed. Explosion prevention and protection methods ap-plied in the process were described including atmospheric inerting, powder inerting and venting. Atmospheric inerting is the main method to prevent dust explosions in this proc

Read More

Dynamic steam inerting system for a ball tube mill

2017.8.29 Date Unit/miU Operating condition at Damage to coal time of incident mill system 3-24-78 6-9-78 6-11-78 7-31-78 8-22-78 11-20-78 7/B ~ Manual mill trip Yes 7/B Mill start, first turn Yes 7/A Mill shutdown, stripping Yes 8/A 2 Mill start, first turn No 8/B Mill shutdown, stripping Yes

Read More

A statistical analysis of coalmine fires and explosions in China

2019.1.1 The interchangeability of fires and explosions led to 79% of the large-scale coalmine fires and explosions in recent years. As ignition sources, blasting work, self-heating and friction and impact caused 86% of the fires and explosions from 2007 to 2016. About 44% of fires and explosions happened in coalmines with central ventilation systems.

Read More

Historical Trends in the Occurrence of Fires and

2023.9.18 It sought a description of mill systems, unit hardware, and characterization of the coal. For the most part, the Riley Stoker survey respondents were plant managers and operators. In this report, the term "explosion" encompasses both severe puffs (structure deformation) and true explosions (containment breaching). The term

Read More

sbm/sbm coal crusher fire hazard.md at main dihog/sbm

Contribute to dihog/sbm development by creating an account on GitHub.

Read More

Dynamic steam inerting system for a ball tube mill

2017.8.26 Date Unit/miU Operating condition at Damage to coal time of incident mill system 3-24-78 6-9-78 6-11-78 7-31-78 8-22-78 11-20-78 7/B ~ Manual mill trip Yes 7/B Mill start, first turn Yes 7/A Mill shutdown, stripping Yes 8/A ~ Mill start, first turn No 8/B Mill shutdown, stripping Yes

Read More

Experts Say Coke Plants Full Of Dangers, Yet Still Safe

2010.7.16 Bruce Steiner, president of the American Coke and Coal Chemicals Institute, said more common accidents at coke plants involve workers falling, getting pinched between equipment or other similar injuries. "Explosions are pretty rare. I've only heard of maybe two or three in the last five years or so," Steiner said.

Read More

Processes Free Full-Text Risk Assessment of Unsafe Acts in Coal ...

2023.1.21 Even in the context of smart mines, unsafe human acts are still an important cause of coal mine gas explosion accidents, but there are few models to analyze unsafe human acts in coal mine gas explosion accidents. This study tries to solve this problem through a risk assessment method of unsafe acts in coal mine gas explosion

Read More

explosion in balltube pulverizer

Pulverizer Fire and Explosions. Pulverizer housing or burner lines are glowing red; Mill fires require immediate attention to prevent damage to the pulverizer and more damaging mill “puffs” Explosions in a pulverized coal system are normally called “puffs” A mill puff is an explosion in the mill system caused by an explosive combination of coal, air and

Read More

Pulverizer Failure Cause Analysis: FP-1226 Research Project

2021.7.9 This survey includes in put from 21 U.S. utilities, with 69 generating units, 469 coal mills and an average size over 600 MW. PROJECT OBJECTIVES. ... Also, clearing systems to combat mill puffs are required on mills grinding the high moisture, ... Mill Explosions 0 0 2 0 3 0 0 3 1.

Read More

Coal Mine Gas Explosion Vulnerability Assessment Based on

2021.3.17 Gas explosion, which is the main type of accidents reported in coal mines, comes with serious economic and safety consequences. The present work adopts the #x201C;glass heart#x201D; model for assessing the vulnerability of coal mines to gas explosions based on a constructed gas explosion vulnerability assessment index system.

Read More

Dynamic steam inerting system for a ball tube mill

2017.8.29 Date Unit/miU Operating condition at Damage to coal time of incident mill system 3-24-78 6-9-78 6-11-78 7-31-78 8-22-78 11-20-78 7/B ~ Manual mill trip Yes 7/B Mill start, first turn Yes 7/A Mill shutdown, stripping Yes 8/A 2 Mill start, first turn No 8/B Mill shutdown, stripping Yes

Read More

Influence of Volatile Content on the Explosion Characteristics of Coal ...

The coal sample was ground using a crusher and a ball mill and then sieved using a 200 mesh sieve to ensure that the particle size of the sample was less than 75 μm. The minus 200 mesh lignite dust was placed in a crucible and then in a muffle furnace and heated. ... but also in taking necessary measures for preventing coal dust explosions in ...

Read More

Inside the Callide C power station disaster - Financial Review

2021.6.2 Workers at CS Energy’s Callide C coal-fired power station in Central Queensland first noticed something was wrong with unit 4 turbine early in the afternoon of May 25. The 405-megawatt Toshiba ...

Read More

Coal Mill - an overview ScienceDirect Topics

Observer-Based and Regression Model-Based Detection of Emerging Faults in Coal Mills. Peter Fogh Odgaard, ... Sten Bay Jørgensen, in Fault Detection, Supervision and Safety of Technical Processes 2006, 2007. 5.2 Experiments with and design of the regression model-based approach. Operating data from a coal mill is used to compare the fault detection

Read More

Pulverized Coal Explosions in the U.S. Utility Industry

2023.9.18 Laboratory experiments were performed in full scale test rigs that allowed triggering and monitoring coal system explosions on demand. Ignition events remaining within the coal pipe created only weak pressure rise, while ignition events within a simulated pulverizer volume created explosions exceeding 70 bar gage (1015 psig).

Read More

Mill Inerting and Pulverizer/Mill Explosion Mitigation - Mill

2018.3.27 Mill Inerting and Pulverizer/Mill Explosion Mitigation Richard P. Storm richardstorm@innovativecombustion (205) 453-0236 2013 Annual Meeting WWW.PRBCOALS.COM Coal Mills

Read More

The Storm Approach to Coal Pulverizer Optimization

2016.5.3 All coal pipes (and flows to all of the burners from each respective pulverizer) should be balanced and within +/- 2% of the mean flow. Perform a seal air check. Begin the normal pulverizer start sequence. Once normal coal flow is applied to the mill, a full mill test should be conducted. This should include isokinetic coal sampling and dirty ...

Read More